Productbeschrijving:

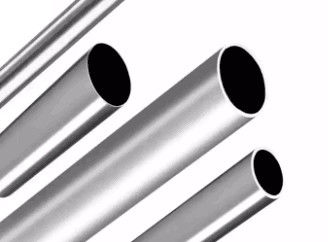

De API 5CT-buizen zijn een product van hoge kwaliteit dat speciaal is ontworpen voor gebruik in de olie- en gasindustrie en dient als een cruciaal onderdeel in boorapparatuur en olieveldbuizen.Gemaakt volgens strenge industriële normen, deze buizen zijn ontworpen om uitzonderlijke sterkte, duurzaamheid en betrouwbaarheid te bieden onder de veeleisende omstandigheden in olie- en gaswinningsprocessen.De veelzijdigheid en de robuuste constructie maken het een essentiële keuze voor exploitanten die op zoek zijn naar efficiënte en veilige olie- en gasleidingen.

Een van de kenmerken van de API 5CT-buizen is de precieze draadspitsopties, waaronder 8, 10, 12, 14, 16, 18 en 20 draden per inch.Deze variaties in draadhoogte zorgen voor compatibiliteit met een breed scala aan verbindingssoorten en boorinstallaties, waardoor naadloze integratie met bestaande apparatuur wordt gewaarborgd.Het draadontwerp vergemakkelijkt niet alleen veilige verbindingen, maar verbetert ook de algehele prestaties van de buizen door het risico op lekken en mechanische storingen tijdens de werking te verminderen.

De materiaalkeuze voor API 5CT-buizen is een ander cruciaal kenmerk dat de geschiktheid ervan voor olieveldbuizen onderstreept.en P110, elk met verschillende mechanische eigenschappen die zijn afgestemd op de verschillende operationele vereisten.waardoor het ideaal is voor standaard booroperatiesDe N80- en L80-klassen bieden een verbeterde corrosiebestendigheid en een hogere druktolerantie, geschikt voor moeilijker omgevingen.biedt een superieure sterkte en vermoeidheidsbestandheid, waardoor het de voorkeur krijgt voor diepe putten en zeer veeleisende omstandigheden in olie- en gasleidingen.

Oppervlaktebehandeling speelt een belangrijke rol bij het verlengen van de levensduur van API 5CT-buizen door ze te beschermen tegen corrosie en slijtage.Deze buizen zijn verkrijgbaar met verschillende oppervlaktebehandelingen zoals fosfateringHet phosphateren zorgt voor een beschermende laag die de corrosiebestendigheid verbetert en de buizen voorbereidt op verdere coatingtoepassingen.Zwart maken zorgt voor een uniforme donkere afwerking die de weerstand tegen roest en slijtage verbetert, terwijl het lakken een extra beschermende coating toevoegt die helpt tegen milieuschade en mechanische slijtage.Deze oppervlaktebehandelingen zorgen ervoor dat de buizen hun integriteit en prestaties behouden gedurende de gehele levensduur, zelfs in moeilijke olieveldomstandigheden.

Het type aansluiting is een cruciaal aspect van API 5CT Tubing, met meerdere opties die geschikt zijn voor verschillende boor- en voltooiingsvereisten.De buizen kunnen worden uitgerust met verbindingen zoals EUE (External Upset End), NUE (Non-Upset End), STC (Short Thread Coupling), LTC (Long Thread Coupling) en BTC (Buttress Thread Coupling).Elk verbindingstype is ontworpen om de mechanische prestaties en lekkageweerstand van de buizenverbindingen te optimaliseren, waardoor de veiligheid en efficiëntie van de booroperaties worden verbeterd.Deze aansluitingsmogelijkheden bieden de exploitanten van olievelden flexibiliteit bij het kiezen van de juiste buisconfiguratie die het beste past bij hun specifieke toepassing en omgevingsomstandigheden.

De API 5CT-buizen zijn ontworpen om compatibel te zijn met verschillende boorexploitaties en kunnen naadloos worden geïntegreerd in de mechanische systemen die worden gebruikt bij de olie- en gaswinning.De robuuste constructie en nauwkeurige fabricage zorgen ervoor dat het bestand is tegen de mechanische spanningen en druk die tijdens de boorwerkzaamheden worden ondervondenDit maakt het tot een onmisbaar onderdeel van de boorexploitatie, dat bijdraagt tot het algemene succes en de veiligheid van de olieveldoperaties.

In het kort, API 5CT Tubing onderscheidt zich als een betrouwbare en veelzijdige oplossing voor olie en gas buizen behoeften.effectieve oppervlaktebehandelingen, en diverse verbindingstypen maken het geschikt voor de strenge eisen van olieveldbuizen.Deze buis zorgt voor de sterkte, duurzaamheid en prestaties die nodig zijn om de functionaliteit van boorapparatuur te optimaliseren en een veilige, efficiënte winning van olie- en gasbronnen te waarborgen.API 5CT Tubing is een voorbeeld van kwaliteit en technische uitmuntendheid in olie- en gasbuisproducten.

Kenmerken:

- Productnaam: API 5CT-buizen

- Draadpitch-opties: 8, 10, 12, 14, 16, 18, 20 draden per inch

- Beschikbare verbindingstypen: EUE, NUE, STC, LTC, BTC

- Gemaakt volgens de normen: API-specificatie 5CT, ISO 11960

- Inspectie en certificering: inspectie door derden, certificaat van de molentest, SGS, BV, DNV

- Materialenklasse: K55, N80, L80, P110

- met een breedte van niet meer dan 50 mm,

- Betrouwbare prestaties en duurzaamheid in API 5CT-buizenproducten

- Ideale oplossing voor het voldoen aan de eisen van de industriestandaarden

Technische parameters:

| Draadpijl |

8, 10, 12, 14, 16, 18, 20 draden per inch |

| Type verbinding |

EUE, NUE, STC, LTC, BTC |

| Buitendeursdiameter |

21.9 - 812.8 mm |

| Materiaal |

K55, N80, L80, P110 |

| Type machine |

Boringsapparatuur |

| Type |

Naadloze stalen buizen |

| Standaard |

API-specificatie 5CT, ISO 11960 |

| Verbinding |

Schommelingen |

| Draadvorm |

Ronde, stevige, speciale bevel |

| Oppervlaktebehandeling |

Fosfateren, zwartmaken, lakken |

Dit API 5CT-buizenproduct is een ideale oplossing voor toepassingen op het gebied van olie- en gasbuizen en biedt een betrouwbare prestatie van olieveldbuizen in verschillende boorexploitaties.

Toepassingen:

De API 5CT-buizen, afkomstig uit China en gecertificeerd volgens ISO 9001, zijn een product van hoge kwaliteit dat speciaal is ontworpen voor verschillende toepassingen in de olie- en gasindustrie.Dit product wordt voornamelijk gebruikt als olie- en gasbuisDe robuuste constructie is gemaakt van hoogwaardige materialen zoals K55, N80, L80,en P110 zorgt voor duurzaamheid en betrouwbaarheid onder extreme omstandigheden, waardoor het de voorkeur krijgt voor hulsbuizen in zowel onshore als offshore booromgevingen.

Een van de belangrijkste toepassingsmogelijkheden voor API 5CT-buizen is in boorapparatuur waar precisie en sterkte van het allergrootste belang zijn.steunstukDeze veelzijdigheid maakt naadloze verbindingssoorten mogelijk zoals EUE, NUE, STC, LTC en BTC,die van cruciaal belang zijn om veilige en lekkagevrije verbindingen in olie- en gasbuizen te garanderen.

API 5CT-buizen zijn ideaal voor scenario's waarbij betrouwbare behuizingsbuizen nodig zijn om de put te beschermen en te ondersteunen tijdens de boor-, voltooiings- en productiefasen.Beschikbaarheid in meerdere soorten zoals K55 voor algemeen gebruik, N80 en L80 voor verbeterde sterkte en corrosiebestendigheid, en P110 voor hogedruk, hoge temperatuur putten, maakt het aanpasbaar aan verschillende geologische en operationele omstandigheden.De verpakking van de buizen in bundels en geweven zakken zorgt voor veilig vervoer en opslag, terwijl de minimale orderhoeveelheid van 1 TON zowel voor kleine als voor grote projecten geldt.

De levering wordt gegarandeerd binnen 40 dagen, afgestemd op de projecttermijnen en de operationele eisen.Voor boorwerkzaamheden upstream of onderhoud en reparatie van bestaande puttenDe API 5CT-buizen zijn een betrouwbaar onderdeel van olie- en gasbuizen die bijdragen aan efficiënte en veilige ontginningsprocessen in de energiesector.

Aanpassing:

Ons API 5CT-buizenproduct, afkomstig uit China en gecertificeerd volgens ISO 9001, biedt uitzonderlijke kwaliteit en betrouwbaarheid voor uw olieveldbuizenbehoeften.We zijn gespecialiseerd in het aanpassen van boorbuizen aan uw specifieke eisen, met een minimale orderhoeveelheid van 1 TON.

De verpakking wordt veilig behandeld met bundels en geweven zakken om een veilige levering te garanderen. De levertijd is gegarandeerd binnen 40 dagen, en we accepteren flexibele betalingsvoorwaarden, waaronder LC, TT en anderen.

De API 5CT-buizen beschikken over een verscheidenheid aan draadspellen, waaronder 8, 10, 12, 14, 16, 18 en 20 draadjes per inch, met aansluitingsmogelijkheden zoals lassen.en P110 voor verschillende bedrijfsomstandigheden.

Inspectie en kwaliteitsborging zijn een prioriteit, met inspectie door derden beschikbaar samen met fabriekstestcertificaten, SGS, BV en DNV certificeringen.en speciale bevelontwerpen om de prestaties te optimaliseren.

Vertrouw op onze op maat gemaakte API 5CT-buizenoplossingen voor superieure olieveldbuizen en boorbuistoepassingen, waardoor efficiëntie en duurzaamheid in uw projecten worden gewaarborgd.

Ondersteuning en diensten:

Onze API 5CT-buizen worden ondersteund door een speciaal technisch supportteam dat uitgebreide ondersteuning biedt gedurende de gehele levenscyclus van het product.toepassingstechniek, en installatieprocedures om optimale prestaties en veiligheid te garanderen.

Onze diensten omvatten gedetailleerde productdocumentatie, met inbegrip van specificaties, testnormen en certificeringen van naleving.We bieden ook trainingsessies en technische workshops om klanten te helpen de beste praktijken te begrijpen voor het gebruik van API 5CT Tubing in verschillende omgevingen.

Daarnaast bieden we inspectie en onderhoudsondersteuning om de levensduur en betrouwbaarheid van de buizen te maximaliseren.het waarborgen van minimale stilstandstijden en operationele efficiëntie.

Wij zijn toegewijd aan voortdurende verbetering en innovatie, en bieden updates over nieuwe technologieën en industriestandaarden met betrekking tot API 5CT-buizen.Ons doel is om uitzonderlijke service en technische expertise te leveren om te voldoen aan de veranderende behoeften van onze klanten..

Verpakking en verzending:

De API 5CT-buizen zijn zorgvuldig verpakt om bescherming tegen beschadiging en corrosie tijdens transport en opslag te garanderen.en bekleed met een roestbestrijdende verbindingDe buizen worden dan met stalen riemen en houten afstandsborden vastgebonden om bewegingen en botsingen te voorkomen.

Voor de verzending wordt de buis op pallets of in containers geladen, afhankelijk van de bestelgrootte en de vereisten voor de bestemming.Alle zendingen voldoen aan de internationale normen en voorschriften voor de scheepvaart om een veilige levering te garanderen.Bij elke zending moet een documentatie worden bijgevoegd, met inbegrip van fabriekscertificaten en inspectieverslagen.

Speciale verpakkingsmogelijkheden zijn op aanvraag beschikbaar om aan de specifieke behoeften van de klant te voldoen of om te voldoen aan specifieke vervoersvoorwaarden.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!