- Ik weet het niet.Inleiding - Ik weet het niet.

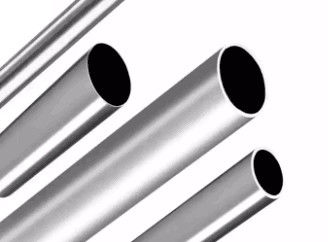

ASTM A213 is een wereldwijd erkende standaard waarin de eisen voornaadloze buizen van ferritisch en austenitisch legerd staalDeze producten zijn bestemd voor hoge temperaturen.T11 (ook aangeduid als 12Cr1MoV in sommige regionale normen) is een essentieel materiaal voor toepassingen waarvoor uitzonderlijke sterkte, thermische stabiliteit,en weerstand tegen kruipen bij verhoogde temperaturenT11-buizen worden veel gebruikt in de elektriciteitsproductie, petrochemie en zware industrie.De Commissie heeft de Commissie verzocht om een verslag uit te brengen over de resultaten van de evaluatie..

In dit artikel worden de technische eigenschappen, productieprocessen, kwaliteitscontrolemaatregelen en toepassingen van ASTM A213 T11-buizen in de praktijk besproken.een gedetailleerde analyse van hun rol in hoogtemperatuurtechnische systemen.

- Ik weet het niet.1. Chemische samenstelling van ASTM A213 T11 - Ik weet het niet.

De mechanische en thermische prestaties van T11-buizen worden fundamenteel bepaald door hun precieze chemische samenstelling, die strikt wordt gereguleerd door ASTM A213.De belangrijkste elementen en hun typische bereik zijn hieronder beschreven:

|

Elementen

|

Samenstellingsbereik (%)

|

Doel/gevolgen

|

| Koolstof (C) |

≤ 0,08·0.12 |

Verbetert de sterkte; hogere koolstof verbetert de hardheid, maar kan de lasbaarheid verminderen. |

| Chroom (Cr) |

1.00 ¥1.50 |

Vormt passieve oxidelagen (bv. Cr2O3) om de oxidatie- en corrosiebestendigheid bij hoge temperaturen te verbeteren. |

| Molybdeen (Mo) |

0.44 ̊0.65 |

Versterkt het materiaal door middel van hardheid in vaste oplossingen en korrelverfijning; cruciaal voor kruipbestandheid. |

| Mangan (Mn) |

0.30 ̊0.60 |

Verbetert de hardheid en de treksterkte; neutraliseert zwavel om de breekbaarheid bij warmte te verminderen. |

| Silicium (Si) |

0.17 ‰ 0.37 |

Deoxiderend middel tijdens de staalindustrie; verhoogt de hoogtemperatuursterkte. |

| Fosfor (P) |

≤ 0.025 |

Onzuiverheid; gecontroleerd om broosheid te voorkomen. |

| Zwavel (S) |

≤ 0.010 |

Onzuiverheid; tot een minimum beperkt om de warme ductiliteit en lasbaarheid te verbeteren. |

| Nikkel (Ni) |

≤ 0.30 |

sporenelement; kan de taaiheid in specifieke warmtebehandelde omstandigheden verhogen. |

| Vanadium (V) |

≤ 0.20 |

Optioneel; verfijnt de graanstructuur en verhoogt de kruipbestandheid (in sommige varianten). |

- Ik weet het niet.Sleutelnoot:De uitgebalanceerde samenstelling van T11 met chroom en molybdeen als primaire legeringselementen geeft een unieke combinatie van hoge temperatuursterkte, oxidatiebestendigheid,en thermische vermoeidheidsbestendigheid, waardoor het wordt onderscheiden van lager gelegeerd of niet-gelegeerd staal.

- Ik weet het niet.2. Fysieke en mechanische eigenschappen - Ik weet het niet.

ASTM A213 T11-buizen zijn ontworpen om te werken in omgevingen waar aanhoudende prestaties bij verhoogde temperaturen (tot 760 °C / 1400 °F) van cruciaal belang zijn.Hun eigenschappen worden gevalideerd door middel van strenge tests volgens ASTM-normen.

- Ik weet het niet.2.1 Eigenschappen bij kamertemperatuur- Ik weet het niet.

- •

- Ik weet het niet.Tensile sterkte (UTS): ≥ 415 MPa (60,200 psi)

- •

- Ik weet het niet.Opbrengststerkte (YS): ≥ 205 MPa (29.700 psi)

- •

- Ik weet het niet.Verlenging:≥ 20% (in 50 mm of 2 in.)

- •

- Ik weet het niet.Hardheid:≤ 170 HB (Brinell) of ≤ 175 HV (Vickers)

Deze waarden zorgen ervoor dat het materiaal mechanische spanningen kan weerstaan tijdens de installatie- en de eerste servicefasen.

- Ik weet het niet.2.2 Hoogtemperatuurprestaties - Ik weet het niet.

Het bepalende voordeel van T11 ligt in het gedrag bij verhoogde temperaturen, waar de meeste stalen afbreken door kruip (tijd-afhankelijke vervorming onder constante spanning) en oxidatie.Belangrijkste eigenschappen bij hoge temperaturen zijn::

- •

- Ik weet het niet.De krachtige scheurkracht:Bij 650 °C heeft T11 een minimale 100.000-uurs kruipbreuksterkte van ~140 MPa (~20,300 psi), waardoor het geschikt is voor langdurige bediening in ketels en reactoren.

- •

- Ik weet het niet.Oxideringsresistentie:Chroom vormt een dichte Cr2O3-schaal die de verdere zuurstofdiffusie remt, waardoor gewichtsverlies en structurele afbraak worden beperkt, zelfs na jaren van blootstelling aan hoge temperatuur stoom of rookgassen.

- •

- Ik weet het niet.Thermische vermoeidheid: De lage thermische uitbreidingscoëfficiënt (~ 11,0 × 10−6 /°C) en de hoge thermische geleidbaarheid (~ 45 W/m·K) minimaliseren de interne spanningen tijdens cyclisch verwarmen/koelen, waardoor het risico op scheuren wordt verminderd.

- Ik weet het niet.Productieproces van ASTM A213 T11-buizen- Ik weet het niet.

De productie van T11-buizen vereist in elk stadium nauwkeurigheid om naleving te garanderen van de strikte afmetings- en metallurgische eisen van ASTM A213.

- Ik weet het niet.3.1 Selectie van grondstoffen - Ik weet het niet.

Hoge zuiverheid ijzererts, schroot staal, en legeringselementen (Cr, Mo, Mn, enz.) worden afkomstig om de samenstelling doelen te voldoen.

- Ik weet het niet.3.2 Smelting en raffinage - Ik weet het niet.

- •

- Ik weet het niet.Primaire smelting:Elektrische boogovens (EAF) of inductieovens worden gebruikt om grondstoffen te smelten, waardoor de eerste samenstelling wordt gecontroleerd.

- •

- Ik weet het niet.Secundaire raffinage:Met de ladle-metallurgie (bijv. LF·Ladle-oven) en vacuümontgassing (VD·Vacuum-ontgassing) wordt het staal verder verfijnd, waarbij zwavel, fosfor en opgeloste gassen (O2,H2) om zuiverheid en homogeniteit te verbeteren.

- Ik weet het niet.3.3 Naadloze buisvorming - Ik weet het niet.

T11-buizen worden vervaardigd als:naadloosHet gebruik van twee primaire methoden:

- •

- Ik weet het niet.Mannnesmann-proces (warm piercing):Een verwarmde billet wordt doorboord door een roterende mandrel om een holle schelp te creëren, gevolgd door rollen en rekken om de wanddikte en -diameter te verminderen.

- •

- Ik weet het niet.Vervaardiging van elektrische apparaten:Voor kleinere diameters wordt een verwarmde balk met behulp van hydraulische rollen over een mandrel gedrukt, waardoor nauwkeurige afmetingen worden bereikt door stapsgewijze reductie. - Ik weet het niet.

3.4 Warmtebehandeling- Ik weet het niet.

De warmtebehandeling na de vorming is van cruciaal belang om de microstructuur en mechanische eigenschappen te optimaliseren:

- •

- Ik weet het niet.Normaal worden:Verwarming tot 980°C (1,800°F), gevolgd door luchtkoeling, verfijnt de graanstructuur, waardoor de sterkte en taaiheid toeneemt.

- •

- Ik weet het niet.Temperen:Verwarming tot 700°C (1,290°F) vermindert de resterende spanningen van het normaliseren, waardoor de sterkte en de ductiliteit in evenwicht komen. - Ik weet het niet.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!